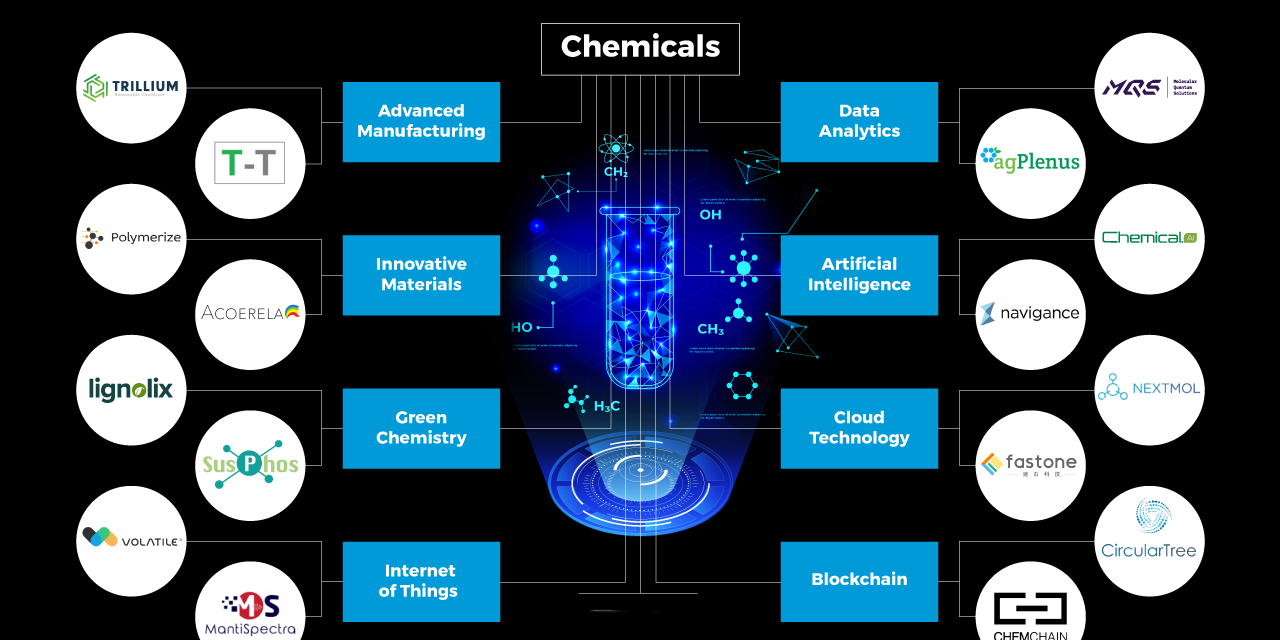

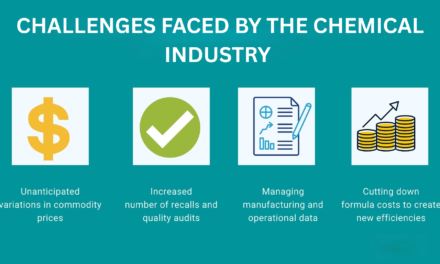

Innovation and technology play a crucial role in the chemical industry, driving improvements in productivity, sustainability, safety, and the development of new products and materials. The chemical industry is highly reliant on technological advancements to stay competitive, reduce environmental impact, and meet the evolving needs of society. Here are the key ways in which innovation and technology influence the chemical industry:

1. Advancing Sustainable Practices

- Green Chemistry: Innovations in green chemistry focus on designing products and processes that reduce or eliminate the use of hazardous substances. This includes developing non-toxic chemicals, safer solvents, and more efficient catalytic processes, all of which minimize the environmental impact of chemical production.

- Energy-Efficient Technologies: Advances in process technology, such as process intensification, help make chemical production more energy-efficient. For example, membrane filtration, micro-reactors, and advanced heat exchangers reduce energy consumption while improving reaction efficiency and yields.

- Carbon Capture and Utilization (CCU): New technologies for capturing carbon dioxide emissions from industrial processes and converting them into useful products, such as chemicals, fuels, or building materials, are helping the chemical industry reduce its carbon footprint.

- Recycling Technologies: Innovations in chemical recycling allow plastic waste to be broken down into its original monomers and reused to produce new, high-quality plastics. This technology supports the shift towards a circular economy by reducing the reliance on virgin raw materials and lowering waste.

2. Development of New Materials

- Advanced Polymers and Materials: The chemical industry has been at the forefront of developing new polymers and composite materials that have a wide range of applications in industries such as aerospace, automotive, electronics, and healthcare. For example, lightweight composites help reduce fuel consumption in vehicles, and smart materials can change properties in response to external stimuli.

- Nanotechnology: The application of nanotechnology in the chemical industry enables the creation of materials with unique properties, such as increased strength, durability, and conductivity, at a much smaller scale. Nanomaterials are used in a variety of applications, including electronics, medicine, and energy storage.

- Bio-based Materials: The development of bio-based chemicals and materials from renewable sources is an important area of innovation. This includes the production of biodegradable plastics, bioplastics, and bio-based solvents, which are more sustainable alternatives to traditional petroleum-based chemicals.

3. Process Optimization and Automation

- Process Automation and Digitalization: The adoption of digital technologies, such as Internet of Things (IoT), artificial intelligence (AI), machine learning, and big data analytics, is transforming chemical production. These technologies enable better control of processes, predictive maintenance, and real-time optimization of production parameters, which lead to higher efficiency and reduced waste.

- Advanced Control Systems: Modern process control systems use sophisticated algorithms to monitor and adjust chemical production processes automatically, improving both yield and safety while reducing human error and downtime.

- Robotics and Automation: The use of robotics in chemical manufacturing plants helps improve the precision of repetitive tasks, reduce labor costs, and minimize human exposure to hazardous substances. Automated systems are also used in laboratory settings for faster and more accurate experimentation.

4. Improvement in Safety and Risk Management

- Predictive Safety: AI and machine learning algorithms are being used to predict potential risks and safety hazards in chemical production. By analyzing historical data and identifying patterns, these technologies can help prevent accidents and improve workplace safety.

- Advanced Sensors: The development of advanced sensors that can detect leaks, gas emissions, and temperature fluctuations in real time helps ensure safety in chemical plants. These sensors enable companies to monitor and address safety concerns before they escalate into serious incidents.

- Digital Twin Technology: Digital twins—virtual replicas of physical systems—allow companies to simulate and optimize chemical processes, identify safety risks, and test different scenarios in a safe environment. This technology helps improve risk management by providing better insight into operations and potential failure points.

5. New Chemical Production Methods

- Catalysis Innovations: Catalysts play a crucial role in increasing the efficiency of chemical reactions, and innovation in catalytic processes can lead to more sustainable and cost-effective production methods. Enzyme catalysts and biocatalysis are emerging as green alternatives to traditional metal-based catalysts, helping to reduce the use of toxic materials and energy consumption.

- Electrochemical Processes: Innovations in electrochemical processes are allowing the chemical industry to produce chemicals in a more energy-efficient way. For instance, electrolysis is used to produce hydrogen, which is essential for the production of ammonia for fertilizers and in various green technologies.

- Biotechnology and Synthetic Biology: Advances in biotechnology and synthetic biology are enabling the production of chemicals and materials through biological processes rather than traditional chemical methods. Microbial fermentation is used to produce biofuels, bioplastics, and bio-based chemicals, reducing the reliance on fossil fuels and enhancing sustainability.

6. Data-Driven Decision Making

- Big Data and AI: The chemical industry is increasingly using big data and AI to enhance decision-making in everything from R&D to manufacturing and distribution. By analyzing vast amounts of data, companies can improve product quality, streamline operations, and better forecast demand.

- Predictive Analytics: Predictive analytics models help chemical companies anticipate market trends, demand shifts, and supply chain disruptions, enabling them to adjust production schedules and optimize inventory management.

- Supply Chain Optimization: AI and machine learning are also being used to optimize supply chains, reduce lead times, and predict potential disruptions. This can help companies minimize costs, improve customer satisfaction, and ensure that products are delivered in a timely and cost-effective manner.

7. Product Innovation and Customization

- Personalized and Specialty Chemicals: Advances in technology are enabling the development of specialty chemicals that are tailored to meet specific customer needs. These chemicals are used in high-value applications such as pharmaceuticals, cosmetics, electronics, and food production.

- Smart Packaging: Innovation in packaging technology is leading to the development of smart packaging solutions that can extend shelf life, reduce waste, and provide real-time information about product freshness and storage conditions. This is especially important in industries like food and pharmaceuticals, where product quality is critical.

8. Collaboration and Open Innovation

- Collaborative R&D: The chemical industry increasingly relies on collaboration with universities, research institutions, and other companies to accelerate innovation. Open innovation platforms are allowing for shared research and development efforts that can result in faster breakthroughs in sustainable technologies and new materials.

- Partnerships with Technology Companies: Chemical companies are partnering with technology firms to leverage expertise in fields like AI, digitalization, and automation. These partnerships help chemical manufacturers stay on the cutting edge of technological advances and apply them to their production processes.

9. Circular Economy and Waste Minimization

- Zero-Waste Technologies: The development of zero-waste production techniques, such as advanced recycling and waste-to-energy technologies, is helping chemical companies reduce their environmental impact. These innovations ensure that by-products and waste materials are reused or converted into valuable products rather than being discarded.

- Upcycling and Waste Valorization: Upcycling involves turning waste materials into higher-value products. This is increasingly being explored in the chemical industry, particularly in relation to plastic waste, through technologies that transform waste into new materials or chemical feedstocks.

Conclusion

Innovation and technology are fundamental to the chemical industry’s ability to address current challenges and capitalize on new opportunities. By leveraging advances in sustainable production, digital transformation, new materials development, and process optimization, the chemical industry is evolving to meet the demands of a more sustainable, efficient, and technologically driven future. As these innovations continue to shape the sector, they will play an increasingly important role in driving growth, improving environmental performance, and enhancing the competitiveness of chemical companies worldwide.

Hashtags

#ChemicalRevolution #InnovativeSolutions #ChemicalAdvancements #TechSavvyChemistry #ChemicalInnovators #SustainableChemistry #TechForChemicals #ChemicalProgress #InnovativeManufacturing #ChemicalBreakthroughs #TechForProgress #ChemicalInnovationHub #SmartChemicals #ChemicalTechTrends #InnovativeChemistry #ChemicalIndustryInnovation #TechForChemicalEngineering #ChemicalInnovationLeaders #FutureChemicals #ChemicalTechRevolution