Latest Advancements in Plastic Extrusion Technology

The plastic extrusion industry is evolving with innovations focused on efficiency, sustainability, and precision. These advancements improve material properties, production speed, waste reduction, and environmental impact. Below are the most recent breakthroughs in plastic extrusion technology:

1. Smart Extrusion Systems and Industry 4.0 Integration

Advancements:

- Adoption of AI-driven process optimization, which automatically adjusts temperature, pressure, and screw speed for consistent quality.

- IoT-enabled extruders with real-time monitoring and predictive maintenance, reducing downtime and maintenance costs.

- Automated quality control systems using laser and infrared sensors to detect variations in thickness and surface finish.

Benefits:

- Higher precision and reduced human error.

- Energy savings through adaptive power consumption.

- Real-time defect detection, minimizing waste and rework.

2. Energy-Efficient and Sustainable Extrusion Processes

Advancements:

- Infrared and induction heating systems replace conventional heaters, reducing energy consumption by up to 40%.

- Energy-efficient screw designs enhance melt homogeneity and reduce processing time.

- Recycling-friendly extrusion for handling post-consumer and industrial plastic waste.

Benefits:

- Lower carbon footprint in manufacturing.

- Significant reduction in energy costs.

- Improved processing of recycled and biodegradable materials.

3. Multi-Layer and Co-Extrusion Innovations

Advancements:

- Advanced multi-layer extrusion for barrier films, medical tubing, and high-performance composites.

- 3D-printed extrusion dies that optimize layer formation and enhance flow control.

- Nanocomposite extrusion incorporating graphene or carbon nanotubes for enhanced strength, conductivity, and heat resistance.

Benefits:

- Creation of functional layers (e.g., UV protection, antimicrobial coatings, oxygen barriers).

- Enhanced material performance while reducing plastic usage.

- Better flexibility and impact resistance in final products.

4. Biodegradable and Bio-Based Polymer Extrusion

Advancements:

- PLA (Polylactic Acid), PHA (Polyhydroxyalkanoates), and bio-PET extrusion for sustainable packaging.

- Development of bio-fiber-reinforced plastics using hemp, bamboo, and other natural fibers.

- Solvent-free extrusion processes that enhance the biodegradability of plastic products.

Benefits:

- Reduction in fossil fuel dependency and plastic waste.

- Expanding applications in food packaging, agriculture films, and medical products.

- Compliance with eco-regulations and circular economy initiatives.

5. High-Precision Medical and Micro Extrusion

Advancements:

- Micro-extrusion for ultra-thin medical tubing, catheter production, and microfluidic devices.

- Bioresorbable polymers (e.g., PEEK, PLGA) for medical implants and drug delivery systems.

- AI-assisted extrusion monitoring to ensure tighter tolerances in critical medical applications.

Benefits:

- Enables minimally invasive medical technologies.

- Improves patient safety with biocompatible and degradable materials.

- Enhanced precision for customized, patient-specific medical devices.

6. Advanced Cooling and Quenching Techniques

Advancements:

- Air and liquid-cooled extrusion with real-time temperature feedback for precise cooling control.

- Vacuum calibration systems that reduce warping and dimensional inconsistencies.

- Cryogenic cooling for ultra-thin films, improving clarity and impact resistance.

Benefits:

- Faster production speeds without compromising material quality.

- Enhanced dimensional stability for complex extrusion profiles.

- Better surface finishes with fewer defects.

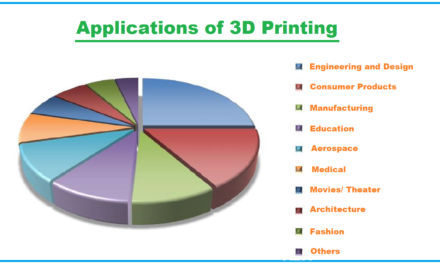

7. Additive Manufacturing and 3D Printing-Enhanced Extrusion

Advancements:

- Hybrid extrusion-3D printing systems that create custom profiles with intricate geometries.

- Direct digital extrusion for on-demand and low-volume manufacturing.

- Extrusion of composite filaments for high-performance engineering applications.

Benefits:

- Reduces material waste and lead time for prototype development.

- Enables custom, small-batch production at lower costs.

- Expands design flexibility beyond traditional extrusion capabilities.

8. AI-Powered Quality Control and Defect Reduction

Advancements:

- AI vision systems detect imperfections in extruded products in real time.

- Machine learning algorithms predict process inefficiencies and recommend adjustments.

- Automated defect correction, minimizing material waste.

Benefits:

- Higher consistency and fewer rejects.

- Less reliance on manual inspection, improving productivity.

- Lower raw material waste, reducing costs and environmental impact.