Future Trends Shaping the Plastic Extrusion Industry

The plastic extrusion industry is evolving rapidly due to advancements in sustainability, automation, material science, and regulatory compliance. Below are the key trends expected to shape the industry in the coming years:

1. Increased Adoption of Recycled and Bio-Based Plastics

Trend:

- Rising global emphasis on circular economy and sustainability is driving the shift toward recycled plastics and bio-based polymers.

- Governments and environmental regulations are restricting single-use plastics, pushing manufacturers to adopt post-consumer recycled (PCR) materials.

- Growth in biodegradable and compostable plastics, such as PLA (Polylactic Acid), PHA (Polyhydroxyalkanoates), and bio-PET, for sustainable extrusion applications.

Impact:

- Reduced dependence on fossil fuel-based plastics.

- Expansion of closed-loop recycling programs in packaging, construction, and consumer goods.

- Investment in advanced recycling technologies to improve material performance.

2. Smart Extrusion Systems with Industry 4.0 Integration

Trend:

- AI-powered process monitoring enables real-time adjustments to temperature, pressure, and extrusion speed, improving quality control.

- IoT-connected extruders provide predictive maintenance alerts, reducing machine downtime and operational costs.

- Digital twin technology is emerging to simulate and optimize extrusion processes before full-scale production.

Impact:

- Higher efficiency and reduced material waste.

- Improved production consistency and automation.

- Lower energy consumption with intelligent power management.

3. Multi-Layer and Co-Extrusion Innovations

Trend:

- Increased demand for multi-layer plastic films and sheets in food packaging, medical devices, and barrier films.

- Use of functional layers to add properties like UV resistance, moisture barriers, antimicrobial protection, and self-healing surfaces.

- Advancements in nanotechnology and composite materials for high-performance extrusion.

Impact:

- Enhanced product properties without increasing material costs.

- Greater applications in smart packaging, automotive components, and medical tubing.

- Expansion into high-tech markets like aerospace and electronics.

4. Energy-Efficient and Sustainable Manufacturing Processes

Trend:

- Infrared and induction heating replacing traditional barrel heaters, reducing energy consumption by 30-40%.

- Implementation of high-efficiency screw designs to improve material mixing and reduce cycle times.

- Waste heat recovery systems are being integrated into extrusion lines to improve sustainability.

Impact:

- Lower operational costs and reduced carbon footprint.

- Compliance with global energy efficiency regulations.

- More environmentally friendly plastic production.

5. Advances in Medical and Micro Extrusion Technology

Trend:

- Growth in micro-extrusion for medical tubing, catheters, and drug-delivery devices.

- Increased use of biocompatible and resorbable polymers for implantable medical components.

- AI-controlled extrusion monitoring ensures ultra-precise production of medical-grade plastics.

Impact:

- Expansion of minimally invasive medical technologies.

- Improved patient safety and biocompatibility.

- Increased demand for customized, patient-specific medical devices.

6. Advanced Cooling and Quenching Techniques

Trend:

- Optimized water and air-cooling systems to prevent thermal deformation in extruded parts.

- Use of vacuum calibration cooling for high-precision profiles in automotive and aerospace applications.

- Cryogenic cooling for ultra-thin film extrusion, improving clarity and impact resistance.

Impact:

- Higher production speeds without compromising material quality.

- Greater dimensional stability in construction and industrial applications.

- Reduction in scrap rates and defective products.

7. Customization and On-Demand Manufacturing with 3D Printing Integration

Trend:

- Hybrid extrusion and additive manufacturing for producing custom parts with intricate geometries.

- 3D-printed extrusion dies and molds to optimize material flow and reduce lead times.

- Growth in direct digital extrusion for small-batch and specialty plastic production.

Impact:

- Faster prototyping and product development.

- Reduced tooling costs and material waste.

- More flexibility in low-volume, high-customization markets.

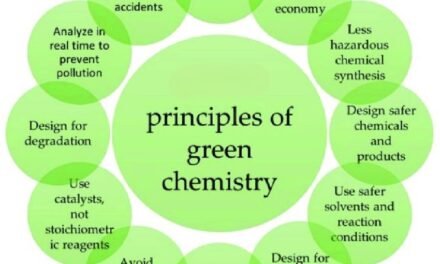

8. Regulatory Compliance and Circular Economy Initiatives

Trend:

- Governments enforcing plastic bans, recycling mandates, and carbon footprint regulations.

- Growth in extended producer responsibility (EPR) policies, requiring companies to manage plastic waste.

- Investment in closed-loop recycling systems and eco-label certifications like ISO 14001.

Impact:

- Increased adoption of recycled plastics and eco-friendly formulations.

- Stricter product life cycle tracking and waste management.

- Expansion of green manufacturing incentives and tax benefits.