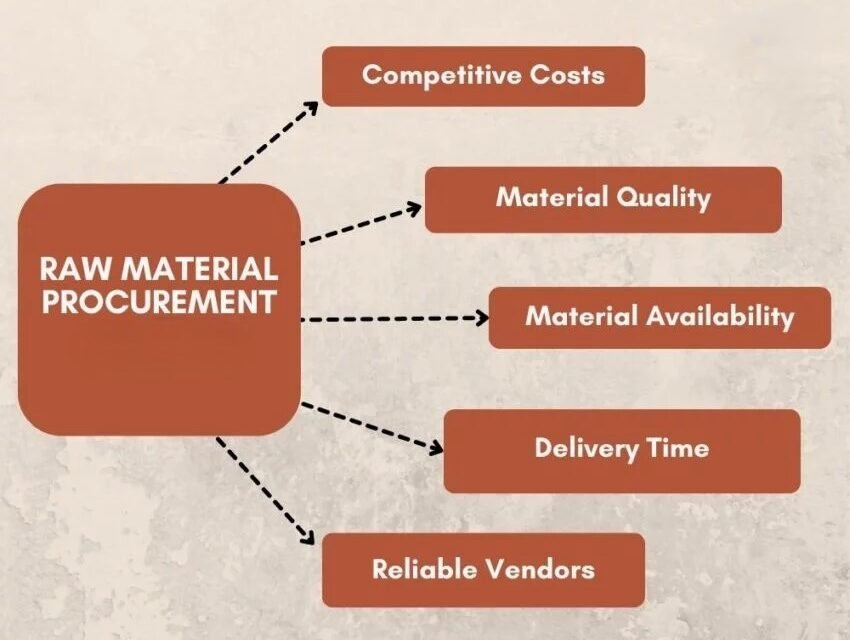

Emerging challenges in raw material procurement for basic chemicals are increasingly complex, driven by geopolitical, economic, environmental, and technological factors. These challenges are reshaping strategies for securing raw materials essential for producing basic chemicals such as sulfuric acid, chlorine, ammonia, and others. Here are the key challenges:

1. Geopolitical Uncertainty

- Trade Restrictions: Export bans, tariffs, and sanctions on key raw materials disrupt supply chains (e.g., restrictions on natural gas, a critical feedstock for ammonia).

- Regional Conflicts: Political instability in resource-rich regions, such as the Middle East and parts of Africa, impacts the steady supply of raw materials like sulfur and hydrocarbons.

- Dependence on Few Suppliers: Overreliance on specific countries for critical inputs (e.g., rare earth elements or natural gas) leaves companies vulnerable to supply chain shocks.

2. Volatile Commodity Prices

- Fluctuating Oil and Gas Prices: Oil and gas are key feedstocks for many basic chemicals, and price volatility directly impacts production costs.

- Metal Price Instability: Due to market dynamics, the cost of metals like copper, zinc, and lead in chemical processes can vary significantly.

- Supply-Demand Imbalances: Sudden changes in demand or disruptions in production can lead to raw material price spikes.

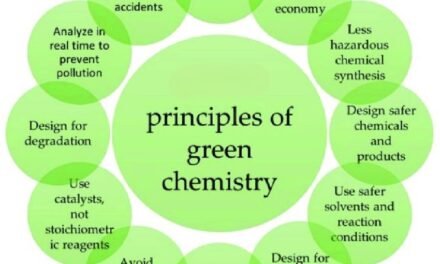

3. Environmental Regulations

- Carbon Footprint Reduction: Stringent rules on greenhouse gas emissions require producers to seek cleaner raw materials, increasing costs and complexity.

- Waste Management: Stricter disposal and recycling regulations for by-products generated during raw material extraction and processing.

- Sustainable Sourcing: Pressure to ensure ethical and environmentally friendly procurement practices for feedstocks like phosphates and sulfur.

4. Supply Chain Disruptions

- Global Transportation Issues: Shipping delays, container shortages, and port congestion affect the timely delivery of raw materials.

- Pandemic After Effects: Residual impacts from COVID-19, including labor shortages and logistical challenges, continue to affect supply chains.

- Natural Disasters: Climate events like hurricanes, floods, and droughts disrupt mining and refining operations.

5. Transition to Renewable Feedstocks

- High Costs: Transitioning from fossil-based to renewable or bio-based feedstocks requires significant investment in new technologies and processes.

- Limited Availability: Sustainable alternatives for key raw materials are still underdeveloped and cannot meet the current scale of demand.

- Technology Gaps: Existing production infrastructure may not be compatible with renewable or circular feedstocks, necessitating retrofitting or new installations.

6. Resource Depletion

- Declining Reserves: Depleting reserves of high-quality ores and fossil fuels make raw material extraction more expensive and energy-intensive.

- Competing Uses: Rising demand for certain raw materials in other industries (e.g., lithium for batteries) creates competition and shortages for the chemical industry.

7. Ethical and Social Concerns

- Human Rights Issues: Scrutiny over labor practices in resource extraction, such as mining for phosphates or metals, creates reputational and legal risks.

- Community Resistance: Local opposition to mining or industrial activities delays projects and increases procurement costs.

8. Technology and Digitalization Gaps

- Lack of Visibility: Inadequate digital integration in supply chains makes tracking and managing raw materials challenging.

- Cybersecurity Risks: Increased reliance on digital systems for procurement and logistics introduces vulnerabilities to cyberattacks.

9. Increased Demand from Emerging Markets

- Rapid industrialization and urbanization in developing economies, particularly in Asia-Pacific and Africa, strain the global supply of raw materials.

10. Circular Economy Pressure

- Recycling Challenges: Scaling up chemical recycling technologies to recover raw materials from waste products is still in infancy.

- Cost Inefficiencies: Implementing circular systems is capital-intensive and may not be economically viable compared to traditional sourcing.

Strategic Responses

To mitigate these challenges, companies are adopting strategies such as:

- Diversifying Suppliers: Reducing reliance on a single region or supplier to improve resilience.

- Investing in Technology: Using AI, blockchain, and IoT for better tracking and forecasting.

- Sustainability Commitments: Partnering with suppliers who adhere to environmental and ethical standards.

- Regional Sourcing: Establishing local supply chains to minimize transportation risks.

Conclusion

Raw material procurement for basic chemicals faces significant headwinds, from geopolitical shifts to environmental pressures. Companies prioritizing diversification, technology adoption, and sustainability will be better equipped to navigate these challenges and ensure long-term stability.

Hashtags

#RawMaterialChallenges #ProcurementTrends #SupplyChainRisks #RawMaterialCrisis #MaterialSourcing #BasicChemicalsIndustry #ChemicalProcurement #BasicChemicals #IndustrialRawMaterials #ChemicalSupplyChain #SustainabilityAndEnvironmentalConcerns #SustainableSourcing #GreenProcurement #EcoSupplyChain #CircularRawMaterials #EnvironmentalChallenges #MarketVolatility #GeopoliticalRisks #GlobalSupplyChain #ResourceScarcity #EconomicUncertainty #DigitalProcurement #SmartSupplyChains #InnovationInChemicals #TechForProcurement #AIInSupplyChain

#IndustryCollaboration #ResilientSupplyChains #FutureOfProcurement #ChemicalIndustryTrends #CollaborativeProcurement #GlobalRawMaterials #RegionalSupplyChain #LocalProcurementIssues #TradeDisruptions