Thermoplastics and thermosetting plastics are two main types of plastics, differing in their chemical structure, properties, and applications. Here’s a detailed comparison of their key differences:

1. Definition

- Thermoplastics:

- Plastics that can be repeatedly melted and reshaped upon heating and solidified upon cooling.

- No chemical change occurs during heating or cooling.

- Example: Polyethylene, polystyrene.

- Thermosetting Plastics:

- Plastics that irreversibly harden upon heating and cannot be reshaped once set.

- Undergo a chemical change during curing (cross-linking of polymer chains).

- Example: Epoxy, Bakelite.

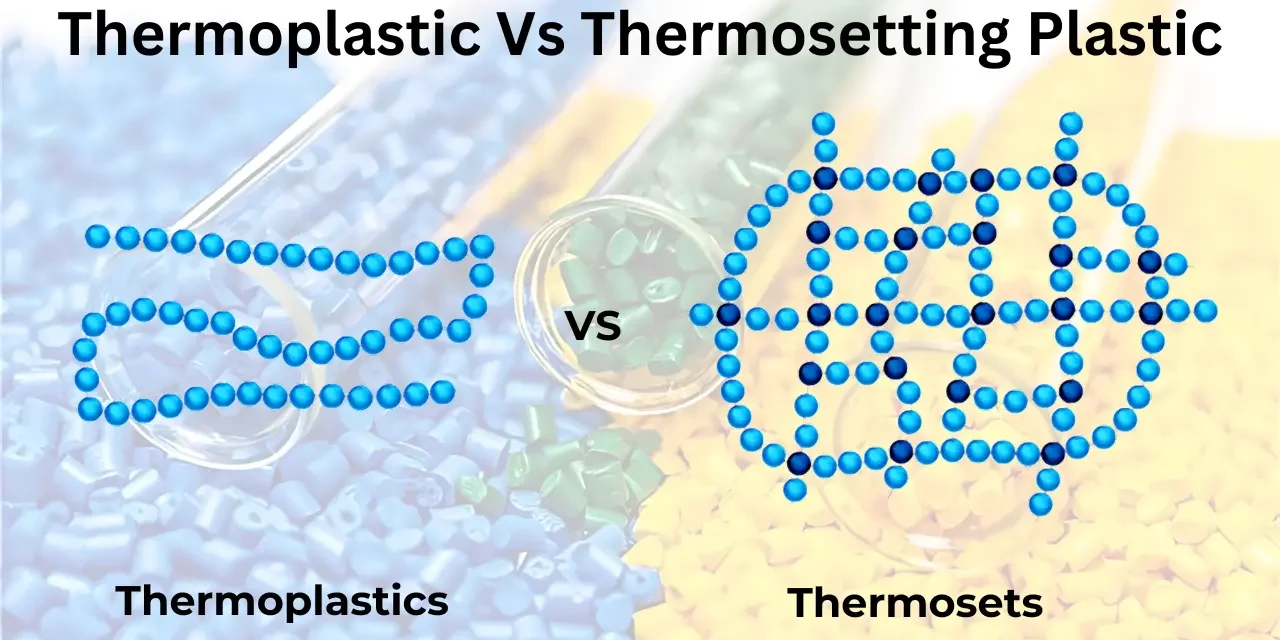

2. Molecular Structure

- Thermoplastics:

- Composed of long, linear or slightly branched polymer chains.

- Chains are held together by weak van der Waals forces.

- No permanent cross-links between chains.

- Thermosetting Plastics:

- Have a highly cross-linked, three-dimensional molecular network.

- Cross-linking creates a rigid and inflexible structure.

3. Thermal Behavior

- Thermoplastics:

- Soften when heated and harden when cooled, allowing for repeated reshaping.

- Retain their properties within aspecificn temperature range but may degrade at high temperatures.

- Example: Melts at specific temperatures (e.g., polyethylene at ~130°C).

- Thermosetting Plastics:

- Harden permanently during the curing process.

- Resistant to high temperatures and do not melt but degrade or char when overheated.

4. Processing and Recyclability

- Thermoplastics:

- Easy to process through methods like injection molding, extrusion, or 3D printing.

- Recyclable due to their ability to be remelted and reshaped.

- Thermosetting Plastics:

- Processing involves curing through heat or chemical agents.

- Not recyclable as they cannot be remelted once cured.

5. Mechanical Properties

- Thermoplastics:

- Flexible and ductile.

- Tend to have lower strength and stiffness compared to thermosets.

- Example: Polyethylene, used in packaging, is soft and pliable.

- Thermosetting Plastics:

- Rigid, strong, and more brittle due to their cross-linked structure.

- Better suited for applications requiring high strength and durability.

6. Chemical Resistance

- Thermoplastics:

- Generally more susceptible to chemical attack, although some, like PTFE (Teflon), are highly resistant.

- Thermosetting Plastics:

- Superior chemical resistance due to their cross-linked structure.

- Suitable for harsh chemical environments, such as industrial tanks and coatings.

7. Applications

- Thermoplastics:

- Commonly used in consumer products, packaging, and lightweight applications.

- Examples:

- Polyethylene (PE): Plastic bags, bottles.

- Polypropylene (PP): Food containers, automotive parts.

- Polyvinyl chloride (PVC): Pipes, window frames.

- Thermosetting Plastics:

- Used in high-strength, high-temperature, and durable applications.

- Examples:

- Epoxy Resins: Adhesives, coatings, electrical insulators.

- Bakelite: Electrical switches, handles of cookware.

- Polyurethane: Foams, coatings, automotive components.

8. Cost and Production

- Thermoplastics:

- Generally more cost-effective and faster to produce due to more straightforward processing.

- High scalability in manufacturing.

- Thermosetting Plastics:

- More expensive and time-intensive due to the curing process.

- Suitable for specialized applications requiring superior properties.

Conclusion

The choice between thermoplastics and thermosetting plastics depends on the application and desired properties. Thermoplastics are favored for versatility and recyclability, while thermosetting plastics are ideal for applications requiring high strength, durability, and resistance to heat and chemicals. Ongoing innovations in both categories continue to expand their applications and sustainability.

Hashtags

#ThermoplasticsVsThermosets #ThermoplasticVsThermosetting #PlasticTypesComparison #PolymersAndPlastics #ThermoplasticsAndThermosets #Thermoplastics #ThermoplasticMaterials #RecyclablePlastics #MeltablePlastics #FlexiblePlastics #ThermosettingPlastics #RigidPlastics #CuredPlastics #HeatResistantPlastics #NonRecyclablePlastics #MeltProcessPlastics #HeatCuringPlastics #ReversiblePlastics #PermanentPlastics #PlasticProperties #ThermoplasticsApplications #ThermosettingPlasticsUses #AutomotivePlastics #ConsumerGoodsPlastics #AerospacePlastics #RecyclableThermoplastics