The explosives and propellants industry faces several challenges due to its critical applications, environmental concerns, and regulatory requirements. Key challenges include:

1. Environmental Impact

- Pollution: Residues from manufacturing and detonation can contaminate soil, water, and air, posing ecological risks.

- Waste Management: Disposal of expired or unused explosives and propellants is complex and hazardous.

2. Safety Risks

- Accidental Detonation: Manufacturing, handling, and storage involve high risks of accidental explosions, requiring stringent safety protocols.

- Worker Safety: Exposure to toxic chemicals and hazardous environments increases health risks for workers.

3. Regulatory Compliance

- Stringent Regulations: Strict environmental, safety, and transport laws impose significant operational and financial burdens on manufacturers.

- Export Controls: International restrictions and licensing requirements limit market expansion.

4. Raw Material Dependence

- Supply Chain Vulnerabilities: Dependence on specific raw materials like ammonium nitrate and RDX makes the industry vulnerable to shortages or price fluctuations.

- Sustainability Concerns: Sourcing non-renewable materials conflicts with global sustainability goals.

5. Rising Costs

- Production Costs: High costs of advanced materials, safety measures, and compliance can affect profitability.

- R&D Investment: Innovation in eco-friendly and high-performance solutions requires significant financial resources.

6. Public Perception and Ethical Issues

- Defense Applications: Association with military use raises ethical concerns and public scrutiny.

- Civilian Safety: Accidents involving civilian-use explosives in mining or construction can damage public trust.

7. Technological Challenges

- Advancing Performance: Meeting the demand for higher efficiency and precision in applications like defense and aerospace requires constant technological innovation.

- Integration of Smart Technologies: Incorporating IoT and AI into traditional systems is a complex and resource-intensive process.

8. Competition from Alternatives

- Non-Explosive Solutions: Safer, non-explosive technologies in mining and construction are emerging as alternatives, reducing demand for conventional explosives.

9. Geopolitical Instability

- Export Restrictions: Trade restrictions and geopolitical tensions can disrupt supply chains and international sales.

- Terrorism Concerns: Strict controls are necessary to prevent misuse, adding layers of complexity to production and distribution.

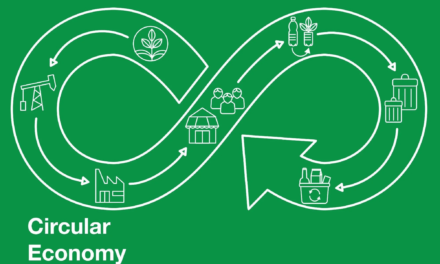

10. Sustainability and Green Chemistry

- Transitioning to eco-friendly propellants and explosives is challenging due to technological and cost barriers.