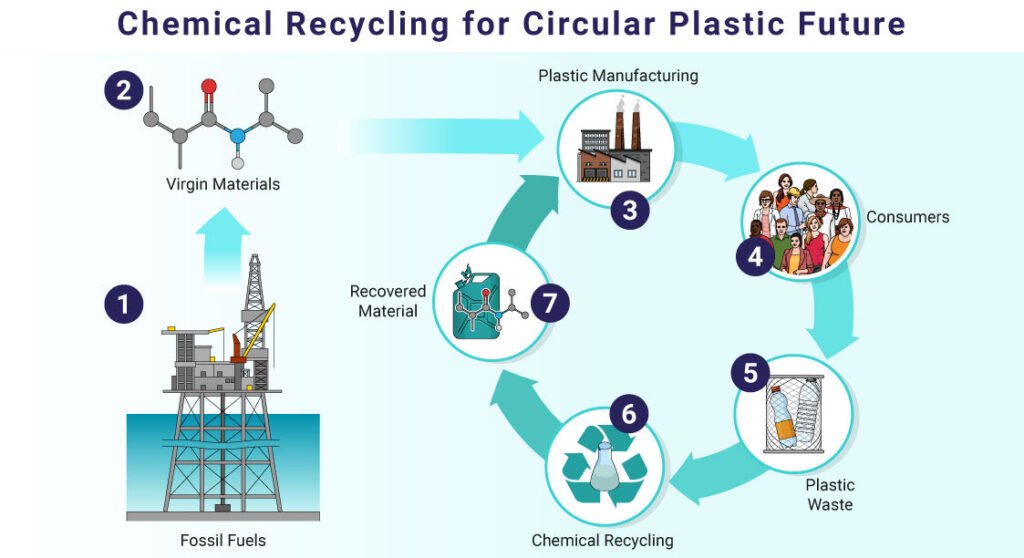

The global plastic waste crisis has accelerated the need for innovative solutions, and chemical recycling is emerging as a transformative approach to tackle the issue. Unlike traditional mechanical recycling, which often struggles with mixed, contaminated, or degraded plastics, chemical innovations are breaking down plastics into their fundamental building blocks, enabling the creation of new materials with properties identical to virgin plastics. Advanced technologies such as pyrolysis, gasification, and depolymerization are at the forefront of this revolution, turning plastic waste into high-value outputs like synthetic oils, monomers, and syngas, which can be used as feedstocks for a wide range of applications. These processes are particularly effective for hard-to-recycle plastics, such as multi-layer packaging and mixed polymers, offering solutions where mechanical methods fall short. Chemical recycling also supports the circular economy by significantly reducing dependency on fossil-based raw materials, cutting greenhouse gas emissions, and extending the lifecycle of plastics without quality degradation. Innovations in catalysts and process efficiencies are further driving down costs and energy requirements, making these technologies more viable for large-scale adoption. Industry collaborations and public-private partnerships are accelerating the development and deployment of chemical recycling facilities, with global players committing to ambitious goals for incorporating recycled content into new products. However, challenges remain, including the high capital investments, energy intensity of certain processes, and the need for robust waste collection systems. Despite these hurdles, chemical innovations in recycling are poised to reshape the future of plastics management, offering a scalable and sustainable solution to one of the world’s most pressing environmental challenges.

Revolutionizing Plastic Recycling with Chemical Innovations