The manufacturing process of fine chemicals differs from that of bulk chemicals in several key aspects, primarily due to differences in production scale, complexity, customization, and cost considerations. Here’s a comparison:

1. Scale of Production

- Fine Chemicals: Produced in small quantities, typically in the range of kilograms to tons per year. Fine chemicals are highly specialized and cater to niche markets, such as pharmaceuticals, agrochemicals, and specialty chemicals.

- Bulk Chemicals: Produced in large volumes, often in the range of thousands to millions of tons per year. These chemicals are used in mass-market applications, such as plastics, fuels, and detergents.

Impact: The scale of production for fine chemicals is much smaller, requiring more flexible and precise processes, while bulk chemicals are produced in large quantities with an emphasis on efficiency.

2. Production Method

- Fine Chemicals: Produced using batch processes, where small quantities of raw materials undergo multiple, controlled steps in a series of reactions. The process is highly customized for each product, involving more intricate operations and quality control.

- Bulk Chemicals: Produced using continuous processes, where raw materials are continuously fed into the system, allowing for large-scale, uninterrupted production. These processes are highly automated, designed for efficiency and high throughput.

Impact: Fine chemicals require more intricate and variable processing steps, whereas bulk chemicals focus on continuous, streamlined operations.

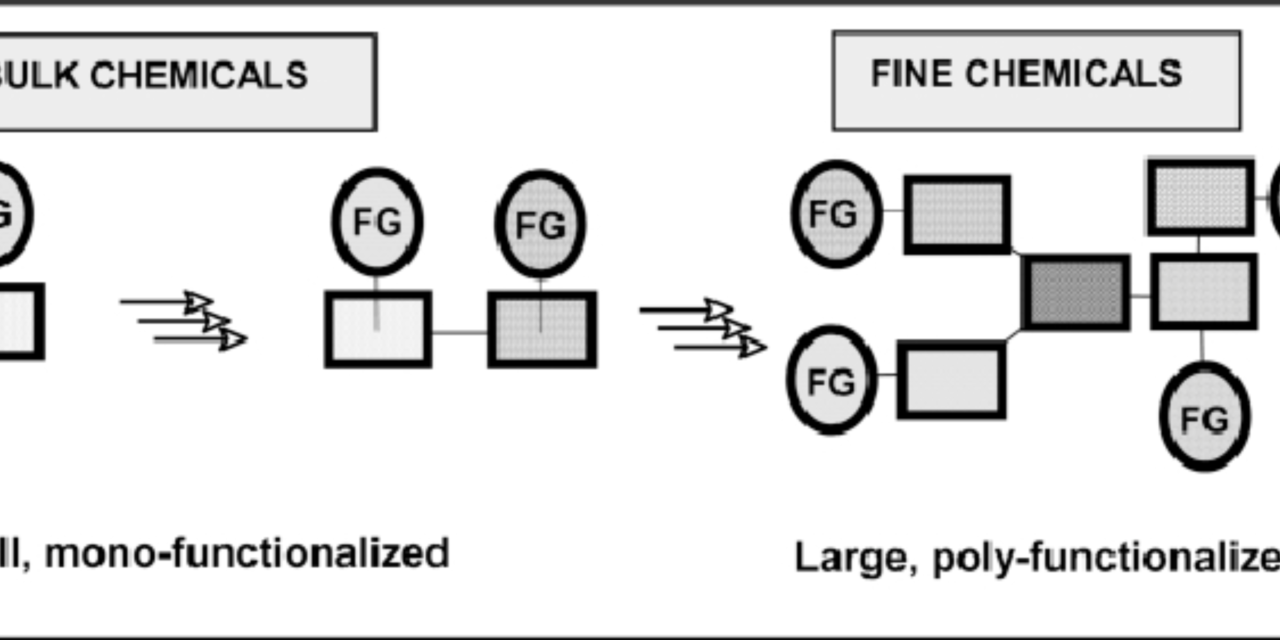

3. Complexity of Products

- Fine Chemicals: Often have complex molecular structures and are customized for specific applications, like active pharmaceutical ingredients (APIs) or specialty agrochemicals. These products may require several specialized reactions and high-quality control standards.

- Bulk Chemicals: Typically have simpler molecular structures, and their production processes are standardized to produce large quantities of consistent product. Examples include common industrial chemicals like ethylene, ammonia, and sulfuric acid.

Impact: Fine chemicals tend to be more labor-intensive to produce, with a focus on quality and precision, while bulk chemicals are easier to manufacture on a large scale due to their simplicity.

4. Cost Structure

- Fine Chemicals: Due to smaller production volumes and highly specialized processes, the production cost per unit is much higher than that of bulk chemicals. Fine chemicals are often sold at a premium price in specialized markets.

- Bulk Chemicals: Produced at much lower costs per unit, thanks to economies of scale and less complex processes. These chemicals are typically sold at lower prices due to their widespread demand.

Impact: Fine chemicals involve higher production costs, but they cater to higher-value, niche markets, whereas bulk chemicals focus on mass production and cost efficiency.

5. Raw Materials

- Fine Chemicals: Often require high-purity raw materials, which may be more expensive or harder to obtain. Fine chemicals might also require the use of specialized reagents and precise formulations.

- Bulk Chemicals: Use more readily available, low-cost raw materials like crude oil, natural gas, and minerals. The focus is on maximizing yield and minimizing cost, so the raw materials are typically abundant and cheap.

Impact: Fine chemicals often need more controlled and specialized raw materials, while bulk chemicals use more basic, inexpensive materials.

6. Regulatory and Quality Control

- Fine Chemicals: Subject to stringent regulatory standards, particularly in industries like pharmaceuticals, cosmetics, and food additives. They must meet high standards of purity, safety, and consistency.

- Bulk Chemicals: While also regulated, the focus is typically on safety, handling, and environmental impact, rather than strict purity standards. Bulk chemicals undergo less rigorous quality control compared to fine chemicals.

Impact: Fine chemicals require extensive quality control, testing, and compliance with specific regulations (e.g., GMP for pharmaceuticals), whereas bulk chemicals are more concerned with safety and environmental regulations.

7. End-Use Applications

- Fine Chemicals: Used in high-value, niche applications like pharmaceutical formulations, agrochemical products, and specialty materials. These chemicals often serve industries that require exact formulations for specific uses.

- Bulk Chemicals: Used in mass-market applications such as plastics, paints, detergents, fertilizers, and energy production. They form the basis of many everyday products.

Impact: Fine chemicals are essential in industries where precision and customization are key, while bulk chemicals are crucial for high-volume industrial applications.

8. Production Time and Batch Size

- Fine Chemicals: Typically produced in smaller batches, which means longer production times. Each batch may require several steps, and the process may be adjusted for each specific batch.

- Bulk Chemicals: Produced in larger, continuous batches, which allows for faster production times and higher output volumes.

Impact: Fine chemicals take longer to produce due to batch processing and customization, whereas bulk chemicals can be produced more rapidly due to continuous, large-scale processes.