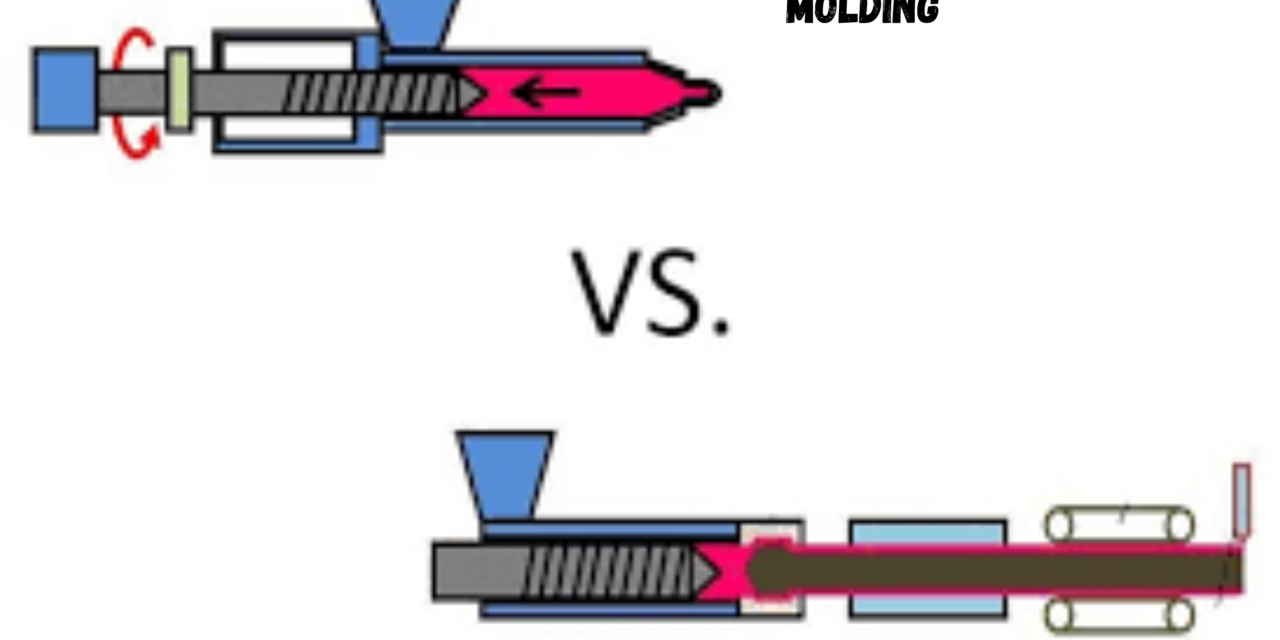

Plastic Extrusion vs. Injection Molding: A Comparison

Both plastic extrusion and injection molding are widely used in plastic manufacturing, but they serve different purposes and are suited for specific applications. Here’s how they compare:

1. Process Overview

Plastic Extrusion

- Involves pushing molten plastic through a shaped die to form continuous profiles.

- Used to create products like pipes, tubing, sheets, films, and window frames.

- The process is continuous, making it highly efficient for long production runs.

Injection Molding

- Involves injecting molten plastic into a closed mold cavity, where it cools and solidifies into the desired shape.

- Used for complex, detailed, and three-dimensional parts such as automotive components, containers, and consumer goods.

- Produces discrete parts, making it suitable for mass production of identical items.

2. Material Usage

Plastic Extrusion

- Works well with thermoplastics, including PVC, polyethylene, polypropylene, and polystyrene.

- Can also process rubber-like elastomers for flexible tubing and seals.

- Material waste is minimal since excess plastic can be re-extruded.

Injection Molding

- Compatible with both thermoplastics and thermosetting polymers.

- Common materials include ABS, polycarbonate, nylon, and polyurethane.

- Scrap plastic from runners and sprues can sometimes be recycled but often generates more waste than extrusion.

3. Applications and Suitability

Plastic Extrusion

- Best for continuous products such as:

- Pipes and tubes

- Window and door frames

- Plastic sheets and films

- Coatings for electrical wires and cables

- Ideal for applications requiring long, uniform cross-sectional shapes.

Injection Molding

- Suitable for complex, detailed parts including:

- Medical devices

- Consumer electronics cases

- Automotive dashboards and components

- Bottle caps, containers, and packaging

- Ideal for applications requiring precision, intricate details, and high repeatability.

4. Production Speed and Efficiency

Plastic Extrusion

- Continuous process allows for high-speed production.

- Suitable for high-volume manufacturing of long-profiled products.

- Post-extrusion cooling and cutting may be required, adding time.

Injection Molding

- Batch process, meaning each cycle produces a set number of parts.

- Cycle times vary (a few seconds to minutes) depending on part size and complexity.

- High initial mold cost, but once set up, the process is fast and efficient for large-scale production.

5. Tooling and Setup Costs

Plastic Extrusion

- Lower tooling costs since dies are simpler compared to injection molds.

- Dies can be reused for multiple production runs with minor modifications.

Injection Molding

- Higher upfront costs due to complex molds, which can be expensive to manufacture.

- Molds must withstand high-pressure injection cycles, requiring strong materials and precise engineering.

- Cost-effective for mass production, as the cost per part decreases with higher volumes.

6. Quality and Surface Finish

Plastic Extrusion

- Produces parts with consistent cross-sections, but surface finish may require post-processing (e.g., trimming, polishing).

- Some die swell may occur, leading to minor variations in dimensions.

Injection Molding

- Offers high precision, tight tolerances, and smooth finishes.

- Mold design allows for texturing, custom finishes, and intricate details.

- Post-processing may be needed for de-flashing or secondary operations.

7. Waste and Environmental Impact

Plastic Extrusion

- Minimizes waste since excess material can be re-extruded.

- Energy-efficient due to its continuous nature.

- Suitable for recycling applications, such as repurposing plastic into films or sheets.

Injection Molding

- Generates waste from runners, sprues, and defective parts, although some can be recycled.

- Uses more energy per cycle compared to extrusion due to high-pressure injection and cooling requirements.

- Innovations in biodegradable and recycled plastics are improving sustainability.

8. Customization and Flexibility

Plastic Extrusion

- Limited to uniform cross-section designs.

- Modifications require new die designs but are generally cost-effective.

Injection Molding

- Allows for complex, intricate geometries and multi-material molding.

- Changes in part design may require new mold fabrication, which can be costly.