Sustainable chemicals play a critical role in reducing the carbon footprint of the chemical industry by promoting energy efficiency, minimizing waste, and decreasing the use of fossil-based raw materials. The chemical sector is one of the largest contributors to global greenhouse gas emissions, so adopting sustainable practices and materials is vital for mitigating its environmental impact. Here’s how sustainable chemicals contribute to this goal:

1. Bio-based Feedstocks

- Contribution: Replacing fossil-based raw materials with renewable, bio-based feedstocks reduces the reliance on petroleum and natural gas, lowering carbon emissions associated with the extraction, refinement, and transportation of fossil fuels.

- Examples:

- Bioethanol and biobutylene are being used to produce bioplastics and bio-based chemicals, such as bio-based polyethylene (PE) and bio-based polyethylene terephthalate (PET), which significantly reduce the carbon footprint compared to their petrochemical counterparts.

- Plant-based oils and sugars are used in the production of biodegradable polymers, solvents, and surfactants, offering an environmentally friendly alternative to traditional synthetic chemicals.

2. Carbon Capture, Utilization, and Storage (CCUS)

- Contribution: Sustainable chemicals can enable or complement carbon capture technologies, which trap carbon dioxide (CO2) emissions from chemical processes and either store them underground or convert them into useful products.

- Examples:

- Carbon capture technology uses solvents, such as amine-based solutions, to absorb CO2 from industrial emissions. The captured CO2 can be repurposed to create synthetic fuels, chemicals, or plastics through carbon utilization processes.

- Biomass conversion technologies convert CO2 into bio-based chemicals or biofuels, reducing overall carbon emissions by sequestering carbon in useful products rather than releasing it into the atmosphere.

3. Energy Efficiency in Chemical Production

- Contribution: The development of sustainable chemicals often involves optimizing chemical processes to reduce energy consumption, which directly lowers carbon emissions from energy production.

- Examples:

- Green solvents like supercritical CO2 and ionic liquids are being used in various chemical processes, reducing the need for energy-intensive distillation or heating processes.

- Advances in catalysis help to lower the activation energy required for chemical reactions, enabling reactions to occur at lower temperatures and pressures, which reduces the energy consumption of chemical manufacturing.

4. Green Chemistry and Process Optimization

- Contribution: Green chemistry principles are designed to minimize environmental impact throughout the chemical lifecycle, from synthesis to disposal. This includes using less toxic reagents, avoiding harmful by-products, and improving process efficiencies.

- Examples:

- Atom economy: Designing reactions that use all the atoms of reactants to form the desired product, minimizing waste and improving yield.

- Solvent-free processes: Using solid-state reactions or liquid-phase synthesis that avoid the need for solvents, thus reducing both chemical waste and energy use.

- Enzymatic catalysis: The use of biocatalysts (enzymes) to carry out chemical reactions at mild conditions (e.g., ambient temperature and pressure), which saves energy and reduces emissions.

5. Recycling and Circular Economy

- Contribution: The implementation of chemical recycling and the development of sustainable chemicals contribute to a circular economy, where chemicals and materials are reused, reducing the need for virgin materials and minimizing waste.

- Examples:

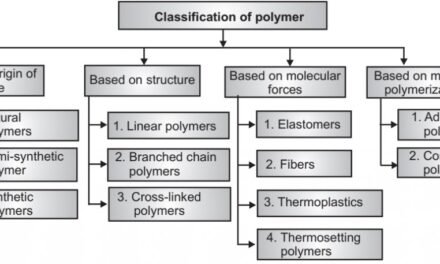

- Chemical recycling technologies like depolymerization (breaking down polymers into their monomers) enable the recycling of plastic waste into high-quality raw materials for new products, reducing the environmental impact of plastic waste.

- Upcycling of waste gases such as methane or carbon monoxide into valuable chemicals or fuels reduces the release of potent greenhouse gases and helps create a more sustainable production cycle.

6. Low-carbon Alternatives in Fuel and Energy

- Contribution: Sustainable chemicals are used in the production of low-carbon fuels and energy sources, reducing the chemical industry’s reliance on fossil fuels and minimizing the overall carbon footprint.

- Examples:

- Biofuels such as bioethanol, biodiesel, and biogas are used as renewable alternatives to petroleum-based fuels in the transportation and industrial sectors, offering a significant reduction in carbon emissions when compared to traditional fossil fuels.

- The development of green hydrogen (produced using renewable energy sources like wind and solar) as a feedstock for chemicals can replace hydrogen produced from natural gas (which typically emits large amounts of CO2).

7. Waste Reduction and Minimization

- Contribution: Sustainable chemicals can be designed to generate minimal waste during their production and use, reducing the environmental burden of chemical manufacturing processes.

- Examples:

- Waste valorization: Chemical processes that convert industrial waste, such as agricultural residues or plastic waste, into valuable chemicals or bio-based products, significantly reducing the need for landfills and incineration, both of which contribute to carbon emissions.

- Closed-loop systems: The development of processes where waste streams are recycled within the system, reducing the need for new raw materials and lowering overall emissions.

8. Bio-based Polymers and Biodegradable Plastics

- Contribution: Bio-based polymers and biodegradable plastics offer significant environmental advantages over traditional petroleum-based plastics, including lower carbon emissions during production and disposal.

- Examples:

- Polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are biodegradable plastics produced from renewable resources like corn or sugarcane, offering a lower-carbon alternative to conventional plastics made from petroleum.

- The development of biodegradable polymers that break down more easily in the environment helps reduce plastic waste and its associated carbon footprint.

9. Sustainable Chemical Packaging

- Contribution: The chemical industry is increasingly adopting sustainable packaging solutions, which reduce the carbon footprint of chemicals by minimizing the use of non-recyclable materials and focusing on reusable or biodegradable options.

- Examples:

- Eco-friendly packaging made from biodegradable materials, such as paper, bioplastics, or recycled plastic, helps to reduce packaging waste and its environmental impact.

- The move towards bulk chemical transportation and refillable containers reduces the demand for single-use packaging and lowers the carbon footprint associated with packaging production.