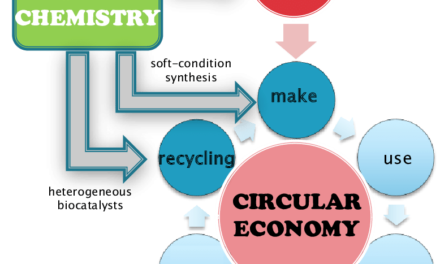

The chemical industry can transition to a circular economy using green chemicals by adopting practices that promote the reuse, recycling, and reduction of materials and resources in chemical production processes. Green chemicals, which are designed to be more sustainable, play a key role in reducing environmental impacts, improving resource efficiency, and enabling a more sustainable lifecycle for chemical products. Here’s how the industry can move towards a circular economy using green chemicals:

1. Designing for Recyclability and Reuse

- Action: The chemical industry can focus on developing products that are easier to recycle or repurpose. This involves using green chemicals to create materials that degrade safely, allowing them to be reused in manufacturing processes or converted into other valuable products at the end of their life cycle.

- Example: The use of biodegradable polymers or bio-based plastics ensures that waste materials can be safely broken down, reducing landfill accumulation and enabling the recycling of chemicals into new products.

2. Chemical Recycling

- Action: Green chemistry can contribute to chemical recycling, where waste materials are chemically transformed back into raw materials that can be reused in the production of new chemicals and products.

- Example: Polymer recycling using chemical processes like depolymerization (breaking down polymers into their monomers) allows plastics to be recycled at a molecular level, thus reusing the raw materials for new plastic production without loss of quality.

3. Minimizing Waste Generation

- Action: Green chemicals can help optimize chemical processes to minimize waste generation. This includes utilizing more efficient processes, reducing by-products, and maximizing the yield of desired chemicals.

- Example: Adopting green solvents and solvent-free processes can help reduce the amount of toxic waste produced during chemical manufacturing. Atom economy (the efficient use of raw materials in reactions) is another principle that minimizes waste in chemical reactions.

4. Sustainable Feedstocks

- Action: Moving from fossil-based feedstocks to renewable, bio-based raw materials is a key part of creating a circular economy. Using sustainable feedstocks reduces the need for virgin resources and lowers environmental impacts.

- Example: Bio-based chemicals, derived from plants, algae, or waste biomass, can replace petroleum-based chemicals, reducing the carbon footprint and reliance on non-renewable resources.

5. Closed-loop Manufacturing

- Action: In a closed-loop system, waste materials generated during manufacturing are recycled back into the production process, reducing the need for new raw materials and lowering emissions.

- Example: A company could set up a process where chemical waste streams (e.g., solvents, catalysts, or by-products) are recovered and purified for reuse in the manufacturing process, thus minimizing waste and conserving resources.

6. Green Chemistry for Upcycling Waste

- Action: Green chemistry techniques can be used to upcycle industrial waste or low-value materials into higher-value products, contributing to a circular economy.

- Example: Waste carbon dioxide (CO2) emissions can be captured and converted into useful chemicals, such as biofuels, polymers, or solvents, using sustainable chemical processes like catalytic conversion or electrochemical reduction.

7. Reducing Toxicity and Environmental Impact

- Action: Green chemicals can help reduce the toxicity of materials, making it safer to recycle or reuse chemicals and materials without harmful environmental effects.

- Example: Non-toxic solvents and eco-friendly alternatives to conventional chemical products (such as paints, coatings, and adhesives) reduce the environmental risks associated with waste disposal and recycling.

8. Biodegradable and Renewable Materials

- Action: Using biodegradable materials that break down naturally at the end of their life cycle reduces the need for waste management and allows for the regeneration of resources.

- Example: PHA (polyhydroxyalkanoates), a biodegradable plastic produced from renewable feedstocks, can be used to create products that decompose naturally, reducing plastic pollution and enabling the reuse of carbon and organic matter.

9. Eco-friendly Packaging

- Action: The chemical industry can adopt sustainable packaging solutions made from renewable or recyclable materials to reduce the waste generated during product transport and use.

- Example: Packaging made from biodegradable materials or recycled plastics reduces reliance on single-use plastic packaging, contributing to a circular system where materials are reused and recycled.

10. Collaboration and Industrial Symbiosis

- Action: Companies can engage in industrial symbiosis, where waste from one industrial process becomes the raw material for another, reducing waste and maximizing resource use.

- Example: The chemical industry can collaborate with other sectors (such as energy or agriculture) to use by-products like waste heat, organic residues, or gaseous emissions as resources for other processes, creating a circular flow of materials and energy.