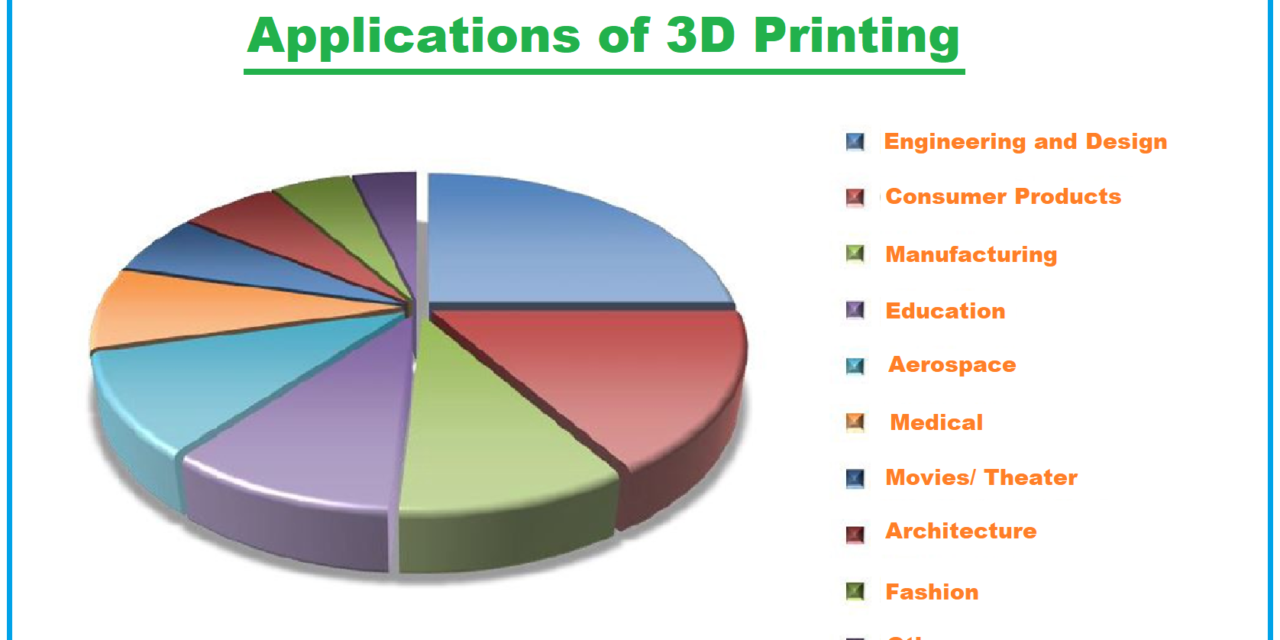

Industrial chemicals are playing a crucial role in enabling and advancing 3D printing (additive manufacturing) across various applications. Here’s how:

1. Development of Advanced Materials:

- Polymers: Chemicals are used to create high-performance polymers such as ABS, PLA, nylon, and PEEK, which are tailored for specific 3D printing processes.

- Resins: Photopolymers, developed using industrial chemicals, are essential for stereolithography (SLA) and digital light processing (DLP) printing.

- Metals and Alloys: Chemicals are used in powder metallurgy to produce fine, printable powders for metal 3D printing, including titanium, aluminum, and stainless steel.

2. Customizable Properties:

- Industrial chemicals enable the formulation of materials with specific properties, such as flexibility, heat resistance, strength, or biocompatibility, to meet diverse application needs.

3. Support for Post-Processing:

- Chemicals like solvents, curing agents, and surface treatments are used in post-processing to enhance the quality and durability of 3D-printed parts.

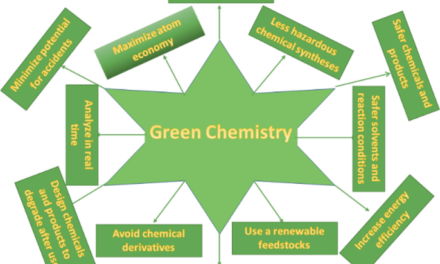

4. Sustainable Alternatives:

- Bio-based and recyclable materials are being developed using green chemistry principles to make 3D printing more environmentally friendly.

5. Functional Inks:

- Conductive inks, loaded with chemicals for electrical conductivity, are enabling the printing of electronic components, circuits, and sensors.

6. Ceramic Printing:

- Advanced ceramic materials, developed with industrial chemicals, are being used in 3D printing applications requiring high-temperature and wear resistance.

7. Composite Materials:

- Chemicals facilitate the integration of fillers like carbon fibers or glass fibers into polymers, creating composite materials for stronger and lighter 3D-printed parts.

8. Applications in Bioprinting:

- Biocompatible hydrogels and bioinks, derived from industrial chemicals, are critical for 3D printing in medical applications, including tissue engineering and organ fabrication.

9. Enhancement of Printing Processes:

- Chemicals are used in binders, adhesives, and reactive agents to improve printing precision, bonding strength, and layer adhesion.

10. Customization and Innovation:

- Custom chemical formulations enable the creation of unique materials tailored for specific industries, such as aerospace, automotive, healthcare, and construction.