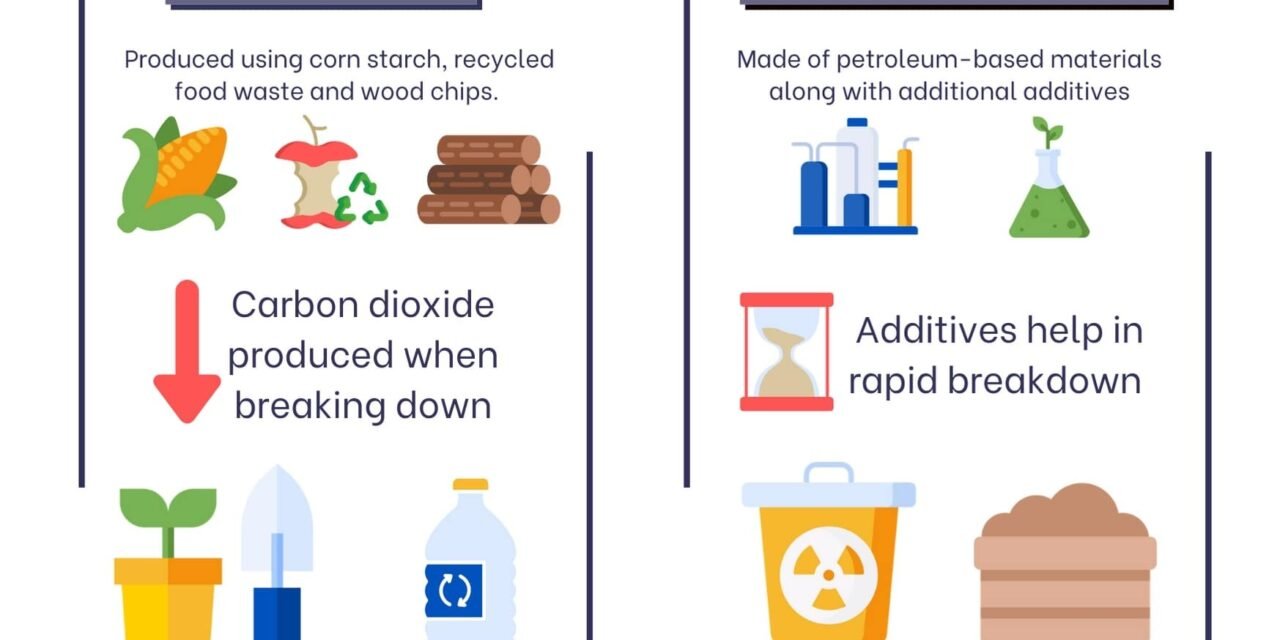

Biodegradable plastics and bio-based plastics differ fundamentally from conventional plastics in terms of raw materials, environmental impact, and end-of-life disposal. Here’s a detailed comparison highlighting these differences:

1. Raw Materials

- Conventional Plastics:

- Derived primarily from petrochemical sources, such as crude oil and natural gas.

- Examples: Polyethylene (PE), polypropylene (PP), polystyrene (PS).

- Non-renewable and finite resources.

- Biodegradable Plastics:

- Can be derived from either renewable (e.g., starch, cellulose) or non-renewable (e.g., fossil-based) sources.

- Designed to degrade under specific environmental conditions through microbial activity.

- Examples: Polylactic acid (PLA), polyhydroxyalkanoates (PHA), and fossil-based biodegradable plastics like polybutylene adipate terephthalate (PBAT).

- Bio-Based Plastics:

- Derived entirely or partially from renewable biomass, such as sugarcane, corn, or algae.

- May or may not be biodegradable.

- Examples:

- Bio-PE: Identical to conventional polyethylene but made from sugarcane ethanol.

- PLA: Derived from corn starch and biodegradable.

2. Environmental Degradation

- Conventional Plastics:

- Highly resistant to degradation; persist in the environment for hundreds of years.

- Break down into microplastics, which accumulate in ecosystems.

- Biodegradable Plastics:

- Decompose into water, carbon dioxide, and biomass under the action of microorganisms.

- Conditions Required:

- Some degrade in natural environments (e.g., PHA).

- Others require industrial composting facilities with specific temperature and humidity (e.g., PLA).

- Bio-Based Plastics:

- Not necessarily biodegradable.

- Bio-PE and bio-PET have the same properties as their fossil-based counterparts and degrade similarly.

3. Environmental Impact

- Conventional Plastics:

- Significant carbon footprint due to fossil fuel extraction and processing.

- Contribute to pollution, especially in oceans and waterways.

- Biodegradable Plastics:

- Reduce long-term waste accumulation if disposed of under the right conditions.

- Potentially reduce carbon emissions, depending on feedstock and production processes.

- Concerns:

- If not properly managed, they may not degrade efficiently in landfills or oceans.

- Bio-Based Plastics:

- Lower carbon footprint during production compared to petrochemical plastics.

- Do not always address issues of long-term waste persistence unless also biodegradable.

4. End-of-Life Options

- Conventional Plastics:

- Recyclable in some instances but often downcycled (recycled into lower-grade products).

- Predominantly end up in landfills or incineration.

- Biodegradable Plastics:

- Degraded biologically, often under industrial composting conditions.

- Not always recyclable; can contaminate traditional plastic recycling streams.

- Bio-Based Plastics:

- May be recycled if chemically identical to conventional plastics (e.g., bio-PE).

- Some types (like PLA) are compostable but require specific conditions.

5. Applications

- Conventional Plastics:

- Broad range of applications, including packaging, automotive, construction, and electronics.

- Examples: Polyethylene for plastic bags, polypropylene for containers, polystyrene for insulation.

- Biodegradable Plastics:

- Focused on short-term or disposable applications:

- Packaging (e.g., compostable bags, food trays).

- Agricultural mulch films.

- Medical applications (e.g., biodegradable sutures).

- Focused on short-term or disposable applications:

- Bio-Based Plastics:

- Used in similar applications as conventional plastics but with renewable sourcing:

- Bio-PE for bottles and packaging.

- PLA for 3D printing and disposable tableware.

- Used in similar applications as conventional plastics but with renewable sourcing:

6. Cost

- Conventional Plastics:

- Typically cheaper due to established supply chains and large-scale production.

- Biodegradable Plastics:

- Generally more expensive because of more minor production scales and specialized processing requirements.

- Bio-Based Plastics:

- Costs depend on feedstock and production methods; often higher than conventional plastics but decreasing as production scales up.

Key Considerations

- Waste Management Infrastructure:

- Biodegradable plastics need proper composting facilities for effective degradation.

- Bio-based plastics like bio-PE can be recycled in existing systems, reducing environmental impact.

- Market Trends:

- Rising demand for sustainable materials is driving innovation in biodegradable and bio-based plastics.

- Policy and Regulation:

- Governments are encouraging the adoption of biodegradable and bio-based plastics through bans on single-use plastics and incentives for sustainable alternatives.

Conclusion

While conventional plastics dominate the market due to cost and versatility, biodegradable plastics and bio-based plastics offer promising alternatives to address environmental concerns. However, they are not interchangeable; their specific applications and environmental benefits depend on their properties and how they are managed at the end of life. Increasing investment in infrastructure, research, and consumer awareness is essential for maximizing their impact.

Hashtags

#BiodegradablePlastics #BioBasedPlastics #SustainablePlastics #GreenPlastics #EcoFriendlyPlastics #BiodegradableVsConventionalPlastics #BioBasedVsPetroleumPlastics #GreenVsConventionalPlastics #SustainablePlasticsVsTraditional #EcoFriendlyPlasticAlternatives #EcoPlastics #ZeroWastePlastics #SustainableMaterials #LowCarbonPlastics #CircularPlastics #SustainablePackaging #CompostablePlastics #EcoPackagingSolutions