The demand for adhesives and coatings in manufacturing is evolving significantly, driven by advancements in technology, environmental regulations, and the need for improved product performance. These materials are increasingly essential in industries such as automotive, construction, packaging, electronics, and healthcare. Here’s a comprehensive analysis of the trends shaping the demand for adhesives and coatings in manufacturing:

1. Shift Toward High-Performance Materials

- Advanced Adhesives:

- Increasing demand for lightweight, high-strength adhesives to replace traditional fasteners (e.g., bolts, screws, welding).

- Examples:

- Structural adhesives in automotive assembly reduce weight and improve fuel efficiency.

- Epoxy and acrylic adhesives in aerospace enhance durability and performance.

- Specialty Coatings:

- Growth in coatings offering corrosion resistance, thermal insulation, UV protection, and enhanced durability.

- Examples:

- Anti-corrosion coatings in construction and industrial machinery.

- Thermal barrier coatings in electronics and energy applications.

2. Rising Adoption of Sustainable Products

- Eco-Friendly Adhesives:

- Manufacturers are increasingly adopting bio-based, water-based, and solvent-free adhesives to meet environmental regulations.

- Example:

- Bio-based adhesives in packaging reduce carbon footprints and enhance recyclability.

- Low-VOC Coatings:

- Coatings with low volatile organic compound (VOC) content are gaining popularity due to stricter environmental standards.

- Example:

- Powder coatings and waterborne coatings in furniture and automotive sectors.

3. Increased Demand in Key Industries

- Automotive and Aerospace:

- Growth in electric vehicles (EVs) and lightweight aircraft increases demand for advanced adhesives and coatings.

- Examples:

- Adhesives for EV battery assembly and coatings for thermal management.

- Construction:

- Rising infrastructure development drives demand for weather-resistant coatings and structural adhesives.

- Examples:

- Polyurethane adhesives for insulation panels and protective coatings for steel structures.

- Electronics:

- Miniaturization of devices and growing IoT adoption require high-performance adhesives and coatings for durability and heat dissipation.

- Examples:

- Conformal coatings for PCBs and thermally conductive adhesives.

- Healthcare:

- Adhesives for medical devices and coatings for antimicrobial surfaces.

- Examples:

- Pressure-sensitive adhesives in wound care and hydrophobic coatings for medical instruments.

4. Technological Advancements

- Innovative Adhesives and Coatings:

- Development of materials with self-healing, responsive, or adaptive properties.

- Example:

- Coatings that change color with temperature or UV exposure for condition monitoring.

- Nano-Enhanced Materials:

- Integration of nanomaterials to improve adhesion, durability, and functionality.

- Example:

- Nano-coatings for scratch resistance and improved water repellency.

5. Customization and Application-Specific Solutions

- Tailored Adhesives:

- Custom formulations to meet specific manufacturing requirements, such as bonding dissimilar materials.

- Example:

- Adhesives for composite materials in aerospace.

- Specialized Coatings:

- Industry-specific coatings, such as anti-graffiti coatings for urban infrastructure or anti-microbial coatings for healthcare.

- Example:

- Coatings for cleanrooms in semiconductor manufacturing.

6. Automation and Process Efficiency

- Compatibility with Automated Systems:

- Adhesives and coatings designed for compatibility with robotic and automated application systems.

- Example:

- Fast-curing adhesives and coatings for high-speed assembly lines.

- Improved Application Techniques:

- Advanced spraying, dipping, and roll-coating methods enhance precision and reduce material waste.

7. Growing Demand for Lightweighting

- Material Substitution:

- Increased use of adhesives to bond lightweight materials like composites, plastics, and aluminum, replacing traditional fasteners.

- Coating Innovations:

- Lightweight protective coatings that offer similar or superior performance to heavier alternatives.

8. Regulatory and Environmental Impact

- Compliance with Regulations:

- Stricter environmental standards drive innovation in low-VOC and non-toxic adhesives and coatings.

- Example:

- Adoption of REACH-compliant products in Europe.

- Circular Economy Integration:

- Development of adhesives and coatings that enable easier recycling or reuse of bonded materials.

- Example:

- Reversible adhesives for modular furniture and electronic devices.

9. Regional Market Insights

- Asia-Pacific:

- Rapid industrialization and growing automotive, construction, and electronics sectors drive demand.

- Example:

- High demand for adhesives in EV manufacturing in China.

- North America and Europe:

- Focus on sustainability and high-performance materials.

- Example:

- Adoption of bio-based adhesives in packaging and advanced coatings in aerospace.

- Middle East and Africa:

- Infrastructure projects and industrial development increase demand for coatings and adhesives.

10. Challenges and Opportunities

- Cost and Scalability:

- High production costs of advanced adhesives and coatings can limit adoption.

- Opportunity:

- Investment in R&D to lower costs and improve scalability.

- Durability vs. Sustainability:

- Balancing long-lasting performance with eco-friendly formulations.

- Opportunity:

- Development of hybrid solutions combining sustainability with high durability.

11. Future Trends

- Smart Manufacturing Integration:

- Adhesives and coatings integrated with Industry 4.0 technologies for real-time monitoring and performance optimization.

- Digital Coatings:

- Coatings embedded with sensors for data collection and IoT connectivity.

- Emerging Markets:

- Growth in developing regions due to increasing industrialization and infrastructure development.

Conclusion

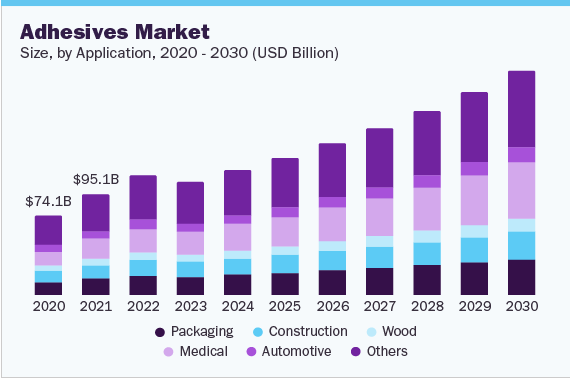

The demand for adhesives and coatings in manufacturing is evolving toward high-performance, sustainable, and application-specific solutions. As industries prioritize lightweighting, sustainability, and advanced technologies, adhesives and coatings are playing a pivotal role in modern manufacturing processes. With continued innovation and integration into diverse applications, the market for these materials is poised for robust growth.

Hashtags

#AdhesivesAndCoatings #ManufacturingMaterials #IndustrialCoatings #AdhesiveTechnologies #MaterialSolutions #MarketGrowthAndTrends #CoatingsMarketTrends #AdhesiveMarketGrowth #GlobalManufacturingDemand #IndustrialMaterialsTrends #FutureOfMaterials #SmartAdhesives #AdvancedCoatings #InnovativeMaterials #TechInManufacturing #NextGenMaterials #AutomotiveAdhesives #AerospaceCoatings #ConstructionMaterials #ElectronicsManufacturing #PackagingSolutions #GreenCoatings #EcoFriendlyAdhesives #SustainableManufacturing #LowVOCCoatings #ClimateSmartMaterials