Renewable feedstocks have the potential to revolutionize essential chemical production by addressing environmental, economic, and resource challenges associated with traditional fossil-based processes. Here’s how they can transform the industry:

1. Reduced Environmental Impact

- Lower Carbon Footprint: Renewable feedstocks like biomass, agricultural residues, and CO₂ help reduce greenhouse gas emissions compared to petroleum-based feedstocks.

- Minimized Pollution: Cleaner production methods using renewable feedstocks produce fewer by-products and less toxic waste.

- Sustainable Resource Use: Renewables are replenishable, reducing reliance on finite resources like crude oil and natural gas.

2. Decarbonizing the Chemical Industry

- Bio-Based Chemicals: Production of basic chemicals like ethanol, methanol, and ethylene from biomass or renewable energy sources supports the transition to a low-carbon economy.

- Green Hydrogen Integration: Hydrogen from renewable energy (solar, wind) can be combined with nitrogen to produce green ammonia, a key input for fertilizers and other chemicals.

- Electrochemical Pathways: Utilizing renewable electricity to power electrochemical processes can replace traditional high-temperature, energy-intensive methods.

3. Circular Economy Enablement

- Chemical Recycling: Renewable feedstocks enable easier recycling and upcycling of materials, aligning with circular economy goals.

- CO₂ Utilization: Capturing CO₂ from the atmosphere or industrial processes and converting it into raw materials for basic chemicals (e.g., methanol) supports carbon-neutral production cycles.

4. Diversification of Feedstocks

- Agricultural Residues: Feedstocks like corn stover, sugarcane bagasse, and wood chips provide alternatives to petrochemical-derived raw materials.

- Algae and Microbial Production: Algae and engineered microorganisms can synthesize precursors for polymers and specialty chemicals, offering scalability and adaptability.

- Waste Conversion: Municipal and industrial waste can be converted into valuable feedstocks, reducing landfill usage and enhancing resource efficiency.

5. Resilience Against Resource Volatility

- Reduced Dependency on Fossil Fuels: Companies can mitigate risks associated with oil and gas price volatility and geopolitical disruptions by using renewable feedstocks.

- Localized Production: Renewable resources can often be sourced locally, decreasing reliance on global supply chains and minimizing transportation costs.

6. Technological Innovations in Production

- Biorefinery Models: Like oil refineries, biorefineries convert biomass into a range of chemicals, fuels, and energy products, ensuring resource efficiency.

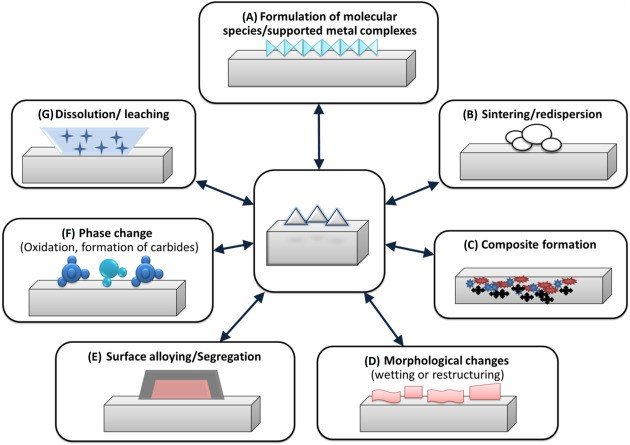

- Catalyst Advancements: New catalysts enable efficient conversion of renewable feedstocks into high-value chemicals, improving process economics.

- Synthetic Biology: Engineered organisms can produce basic chemical building blocks more precisely and efficiently.

7. Emerging Applications

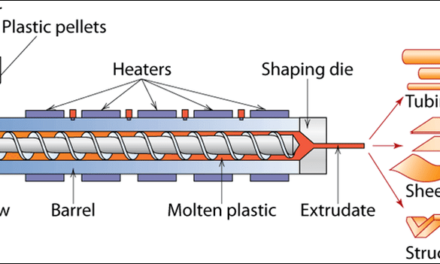

- Bio-Based Polymers: Ethylene and propylene derived from renewable sources can produce plastics with lower environmental impact.

- Renewable Solvents: Bio-based solvents like bio-butanol are finding applications in coatings, adhesives, and cleaning products.

- Green Fertilizers: Ammonia and urea from renewable hydrogen are critical for sustainable agriculture.

Challenges to Adoption

While renewable feedstocks offer significant potential, challenges remain:

- High Production Costs: Initial investments in renewable feedstock technologies are high, making them less competitive with established fossil-based methods.

- Scalability: Limited availability of renewable resources at scale may hinder widespread adoption.

- Technological Barriers: Many renewable feedstock technologies are still in developmental stages, requiring further innovation and commercialization.

- Regulatory and Market Alignment: Government policies and market incentives are essential to drive demand and investment in renewable feedstock solutions.

Future Outlook

Renewable feedstocks are expected to play an increasingly significant role in the chemical industry, driven by:

- Policy Support: Governments worldwide are implementing regulations and incentives to promote green chemistry and renewable feedstock use.

- Corporate Commitments: Many chemical companies are setting ambitious sustainability targets, including transitioning to renewable feedstocks.

- Consumer Demand: Growing awareness and preference for environmentally friendly products create market pressure for renewable alternatives.

Conclusion

Renewable feedstocks represent a transformative opportunity for the chemical industry, offering pathways to sustainability, resilience, and innovation. By addressing existing challenges and scaling up technologies, the industry can unlock the full potential of renewables to revolutionize the production of basic chemicals, paving the way for a greener, more sustainable future.

Hashtags

#RenewableFeedstocks #SustainableChemistry #GreenFeedstocks #RenewableMaterials #FutureOfChemicals #ChemicalInnovation #RenewableChemicals #GreenChemicalProduction #BioBasedChemicals #ChemicalRevolution #EnvironmentalSustainability #SustainableProduction #LowCarbonChemistry #EcoFriendlyManufacturing #NetZeroChemicals #EmergingTechnologies #CircularEconomy #TechForSustainability #CircularChemicals #BioRefineries #IndustryCollaboration #GlobalGoals #CollaborationForChange #SustainableIndustry #ChemicalTransition

#PolicyAndAdvocacy #GreenPolicy #SustainableDevelopment #CleanEnergyForChemicals #DecarbonizationGoals #FutureOfManufacturing