Acrylic production, traditionally reliant on petrochemical feedstocks, is undergoing a transformation driven by sustainability and green chemistry principles. As industries seek eco-friendly alternatives, acrylic manufacturers are innovating to reduce environmental impact while maintaining material performance.

1. The Environmental Challenges of Conventional Acrylic Production

Acrylic materials, such as polymethyl methacrylate (PMMA), are widely used in automotive, construction, and consumer goods. However, conventional production poses several sustainability challenges:

- High Carbon Footprint: Derived from petroleum, acrylic production contributes to greenhouse gas emissions.

- Toxic Solvents & Byproducts: Traditional synthesis methods involve hazardous chemicals like methyl methacrylate (MMA), leading to waste and pollution.

- Non-Biodegradability: Acrylic plastics persist in landfills, adding to plastic waste concerns.

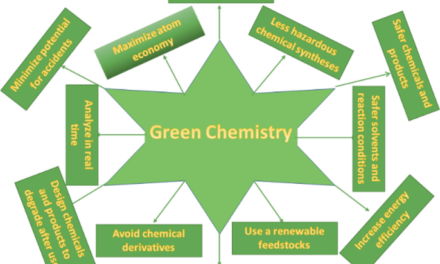

2. The Role of Green Chemistry in Acrylic Manufacturing

Green chemistry focuses on reducing waste, energy consumption, and toxic byproducts. Several advancements in acrylic production align with these principles:

a) Bio-Based Acrylics

- Companies are developing bio-based methyl methacrylate (bio-MMA) from renewable sources such as plant-derived sugars, glycerol, and agricultural waste.

- These alternatives reduce reliance on fossil fuels and lower carbon emissions.

- Example: Mitsubishi Chemical and Arkema are investing in bio-based acrylic resins.

b) Recycling & Circular Economy Initiatives

- Chemical recycling technologies break down used acrylics into monomers, allowing closed-loop production.

- Mechanical recycling techniques are improving, though maintaining optical clarity in recycled PMMA remains a challenge.

- Example: Lucite International’s Infinite Acrylic™ project aims for 100% recyclability.

c) Low-VOC & Water-Based Formulations

- Acrylic coatings, adhesives, and paints are shifting from solvent-based to water-based formulations, reducing volatile organic compounds (VOCs).

- This shift improves indoor air quality and aligns with regulatory restrictions.

d) Process Optimization & Energy Efficiency

- Innovations such as catalysis improvements and microwave-assisted polymerization reduce energy consumption.

- Green solvents, such as ionic liquids, are replacing hazardous chemicals.

3. Industry Trends & Future Outlook

The demand for sustainable acrylics is rising due to regulatory pressures and consumer awareness. Key trends include:

- Eco-labeling & Certification: Brands using sustainable acrylics gain a competitive edge.

- Advanced Recycling Technologies: Expect further developments in depolymerization and reuse.

- Increased Investment in Green Chemistry: Research into bio-based polymers is expanding rapidly.