Adopting green chemistry practices offers significant environmental and economic benefits, but companies face several challenges in implementing these practices across their operations. These challenges include technological, financial, regulatory, and organizational hurdles that can slow down or complicate the transition to more sustainable chemical processes. Below are the main challenges companies face when adopting green chemistry practices:

1. High Initial Investment Costs

- Challenge: Transitioning to green chemistry often requires significant upfront investments in new technologies, equipment, and research and development (R&D).

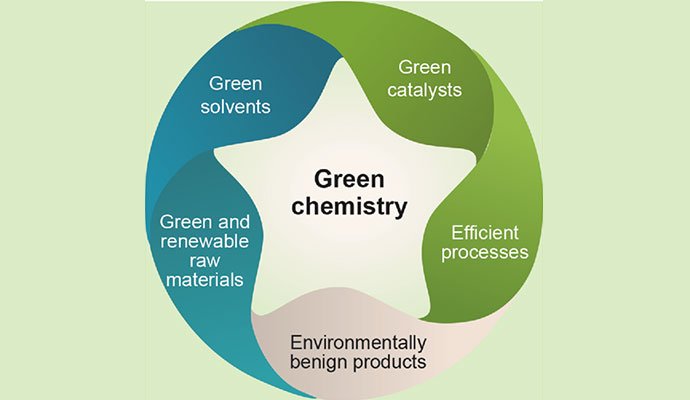

- Impact: Developing and scaling up green processes, such as those involving bio-based feedstocks, green solvents, or alternative catalysis, can be expensive. This can be a barrier, particularly for small and medium-sized enterprises (SMEs) with limited financial resources.

- Example: The cost of switching from petroleum-based raw materials to renewable bio-based alternatives can involve considerable upfront costs for sourcing and processing new materials.

2. Technological and Process Adaptation

- Challenge: Existing chemical processes may not be compatible with green chemistry approaches, and adapting or redesigning them to be more sustainable can be complex.

- Impact: Many traditional processes in chemical manufacturing are energy- and resource-intensive. Shifting to greener methods, such as enzymatic catalysis or supercritical CO2 extraction, requires changes to infrastructure, processes, and operational practices.

- Example: Companies may need to redesign production lines or adopt new reaction conditions (e.g., lower temperatures or pressures) to align with green chemistry principles, which may not be straightforward or cost-effective initially.

3. Lack of Market Demand or Consumer Awareness

- Challenge: Despite growing interest in sustainability, many companies face challenges in convincing customers to prioritize or pay more for green chemistry products.

- Impact: Without significant demand for sustainable products, companies may be reluctant to invest in green chemistry. The market may not fully value the environmental benefits, or consumers may not be willing to pay higher prices for green alternatives.

- Example: In sectors like plastics or chemicals, traditional, cheaper products may still dominate the market, making it harder for eco-friendly alternatives to gain a foothold.

4. Regulatory and Compliance Issues

- Challenge: While there is increasing regulatory pressure for companies to reduce their environmental impact, the regulatory landscape surrounding green chemistry can be complex and inconsistent across regions.

- Impact: Navigating a patchwork of local, national, and international regulations can be difficult for companies, especially in industries that are heavily regulated. Green chemistry practices may not always align with existing safety or environmental standards.

- Example: Some green solvents or bio-based chemicals may not have clear regulatory pathways for approval, delaying their introduction to the market.

5. Limited Availability of Green Raw Materials

- Challenge: Sourcing sustainable, renewable, or bio-based raw materials in sufficient quantities can be a significant challenge, particularly when the supply chains are not well-established or are limited in scope.

- Impact: The availability of green feedstocks, such as bio-based monomers or renewable chemicals, can fluctuate due to factors like agricultural yields, land use, and competition from other industries (e.g., food and fuel).

- Example: Bio-based chemicals may face supply chain disruptions or price volatility, making it difficult to secure consistent, sustainable raw materials for large-scale production.

6. Lack of Skilled Workforce

- Challenge: The shift to green chemistry often requires specialized knowledge in areas such as sustainable chemistry, environmental science, and green engineering, but there may be a lack of professionals with the right expertise.

- Impact: Developing new green processes or scaling up existing ones requires skilled researchers, engineers, and technicians who are well-versed in sustainable practices and technologies. A shortage of these experts can slow down the adoption of green chemistry.

- Example: Companies may struggle to recruit scientists and engineers who are proficient in alternative materials, green catalysis, or environmentally friendly process design.

7. Performance and Efficiency Trade-offs

- Challenge: Green chemistry solutions may not always offer the same level of performance, efficiency, or yield as traditional chemical processes.

- Impact: Shifting to more sustainable processes often involves trade-offs in terms of reaction rates, selectivity, or overall product yield. These trade-offs can affect the economics of the process and make it harder for green alternatives to compete with established methods.

- Example: Bio-based plastics or biodegradable materials may have different performance characteristics (e.g., durability or strength) compared to petroleum-based counterparts, which could limit their use in certain applications.

8. Economic Viability and Scalability

- Challenge: While green chemistry can be environmentally beneficial, the economic viability of sustainable processes on a large scale is still a significant challenge.

- Impact: For green chemistry to be widely adopted, it must be economically competitive with traditional chemical processes. The cost of green chemicals and materials needs to decrease over time as production volumes increase, but scaling up these new technologies can be expensive.

- Example: Producing bio-based ethylene from renewable sources may initially be more expensive than traditional fossil-derived ethylene. However, achieving economies of scale and reducing costs over time requires substantial investment in production facilities.

9. Supply Chain Challenges

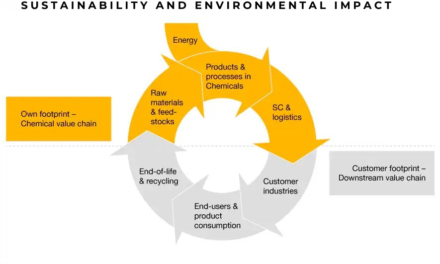

- Challenge: The supply chain for sustainable chemicals is often not as established or reliable as that for traditional chemicals, leading to potential disruptions or inconsistencies.

- Impact: Green chemistry practices may require more complex or new supply chains that need to be developed and managed. This includes ensuring that raw materials are sustainably sourced and ensuring transparency and traceability.

- Example: Sourcing sustainable bio-based feedstocks from agriculture can be subject to weather conditions, land-use practices, and competition for resources, creating variability in availability and cost.

10. Consumer and Investor Pressure

- Challenge: Companies may face pressure from both consumers and investors to adopt green chemistry practices, but balancing these demands with profitability and operational feasibility can be difficult.

- Impact: Meeting the growing demand for sustainable products requires companies to balance short-term financial pressures with long-term sustainability goals. Investors may push for immediate returns, making it challenging for companies to make long-term investments in green chemistry.

- Example: Companies may need to justify the additional upfront costs of transitioning to green chemistry practices to shareholders and customers, which can be challenging in a competitive market.