Continuous manufacturing (CM) in pharmaceuticals has immense potential to revolutionize the industry by improving efficiency, product quality, and scalability. Here’s an overview of its potential:

1. Improved Efficiency

- Faster Production: Continuous manufacturing eliminates batch production delays, enabling faster production cycles.

- Higher Throughput: Materials flow seamlessly through the process, reducing downtime and maximizing output.

2. Enhanced Product Quality

- Real-Time Monitoring: Advanced sensors and Process Analytical Technology (PAT) enable real-time quality control, minimizing deviations.

- Consistent Quality: Continuous systems produce uniform product quality by avoiding batch-to-batch variability.

3. Cost Reduction

- Lower Operational Costs: CM reduces labor, energy, and raw material costs by optimizing resource utilization.

- Reduced Waste: Precise process control minimizes waste and rework, leading to cost savings.

4. Faster Time to Market

- CM shortens production timelines, allowing faster response to market demands and regulatory approvals.

5. Scalability and Flexibility

- On-Demand Production: CM systems can scale production up or down quickly to meet market demands without significant reconfiguration.

- Multi-Product Capability: Flexible CM setups allow rapid transitions between different drugs.

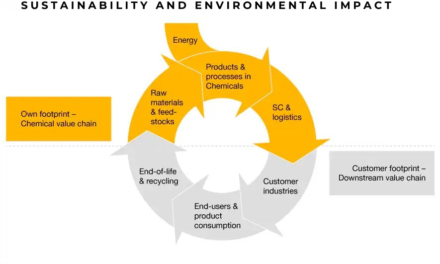

6. Enhanced Sustainability

- Energy Efficiency: Continuous processes consume less energy than traditional batch methods.

- Waste Reduction: Lower waste generation aligns with green chemistry principles and environmental goals.

7. Supply Chain Resilience

- CM facilitates localized and decentralized production, reducing dependency on global supply chains and mitigating risks like pandemics or geopolitical disruptions.

8. Facilitating Complex Therapies

- CM is particularly suited for producing biologics, personalized medicines, and advanced therapies like gene and cell treatments, where precision is crucial.

9. Real-Time Release Testing (RTRT)

- Integrated monitoring systems enable immediate quality verification, accelerating regulatory compliance and reducing inventory needs.

10. Innovation in Drug Development

- CM supports rapid prototyping and testing of new formulations, accelerating R&D and innovation cycles.