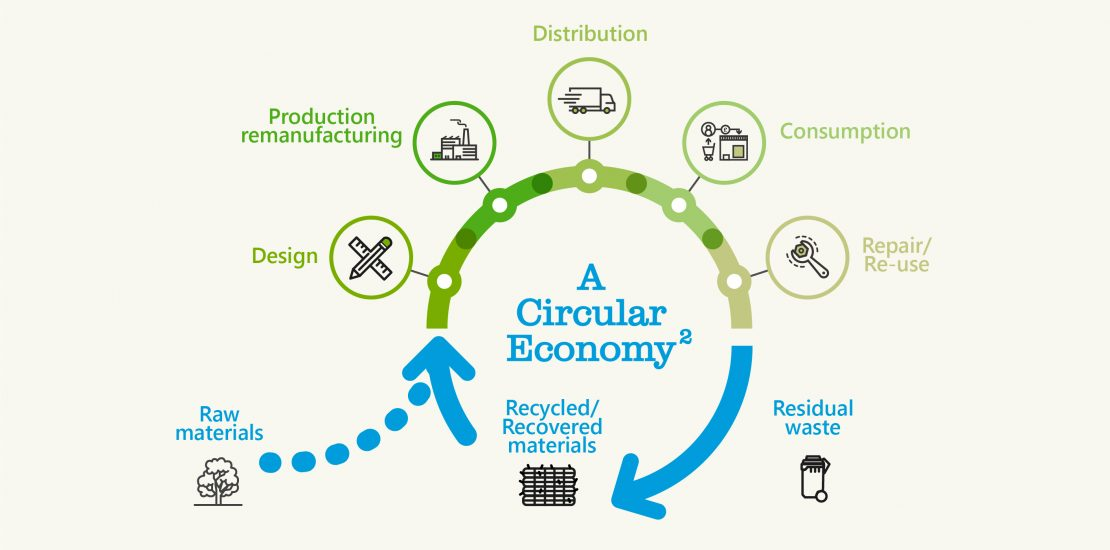

Chemical plants around the world are increasingly adopting circular economy practices, transforming traditional linear production models into closed-loop systems that maximize resource efficiency and minimize waste. This shift is driven by the urgent need to address environmental challenges, regulatory pressures, and growing consumer demand for sustainable products. Circular practices in chemical plants involve innovative approaches such as the use of renewable feedstocks, advanced recycling technologies, and the repurposing of byproducts, ensuring that materials are continually cycled within the economy rather than discarded.

One of the most impactful developments is the rise of chemical recycling, which breaks down plastics and other waste into their molecular components, enabling the creation of new materials with the same quality as those made from virgin resources. Plants are also integrating waste-to-chemical technologies, converting municipal and industrial waste into valuable feedstocks like syngas and methanol. Additionally, byproducts from one production process are increasingly being used as raw materials for another, reducing the need for fresh inputs and lowering overall emissions.

Digital tools, such as AI and IoT, are playing a crucial role in optimizing these circular practices by improving resource tracking, process efficiency, and waste management. Partnerships between chemical companies, governments, and other industries are accelerating the adoption of circular economy initiatives, with collaborations focusing on shared infrastructure, innovation hubs, and sustainable supply chains. Despite challenges like high implementation costs and the need for new regulatory frameworks, circular economy practices are becoming a cornerstone of modern chemical manufacturing, ensuring the industry’s long-term viability while contributing to global sustainability goals.